ESS-ENN Timber AB

In the heart of Småland, Sweden, lies the community of Skruv, where ESS-ENN Timber runs its glulam production – now completely fossil-free.

The mission

ESS-ENN Timber’s guiding principle is “environmentally friendly wood products with endless possibilities”. In keeping with this motto, they set out early on to switch from fossil fuels to bioenergy. Today, ESS-ENN Timber uses bioenergy for its production and for heating its premises.

Client:

ESS-ENN Timber AB

Industry:

Wooden goods

Solution/Product:

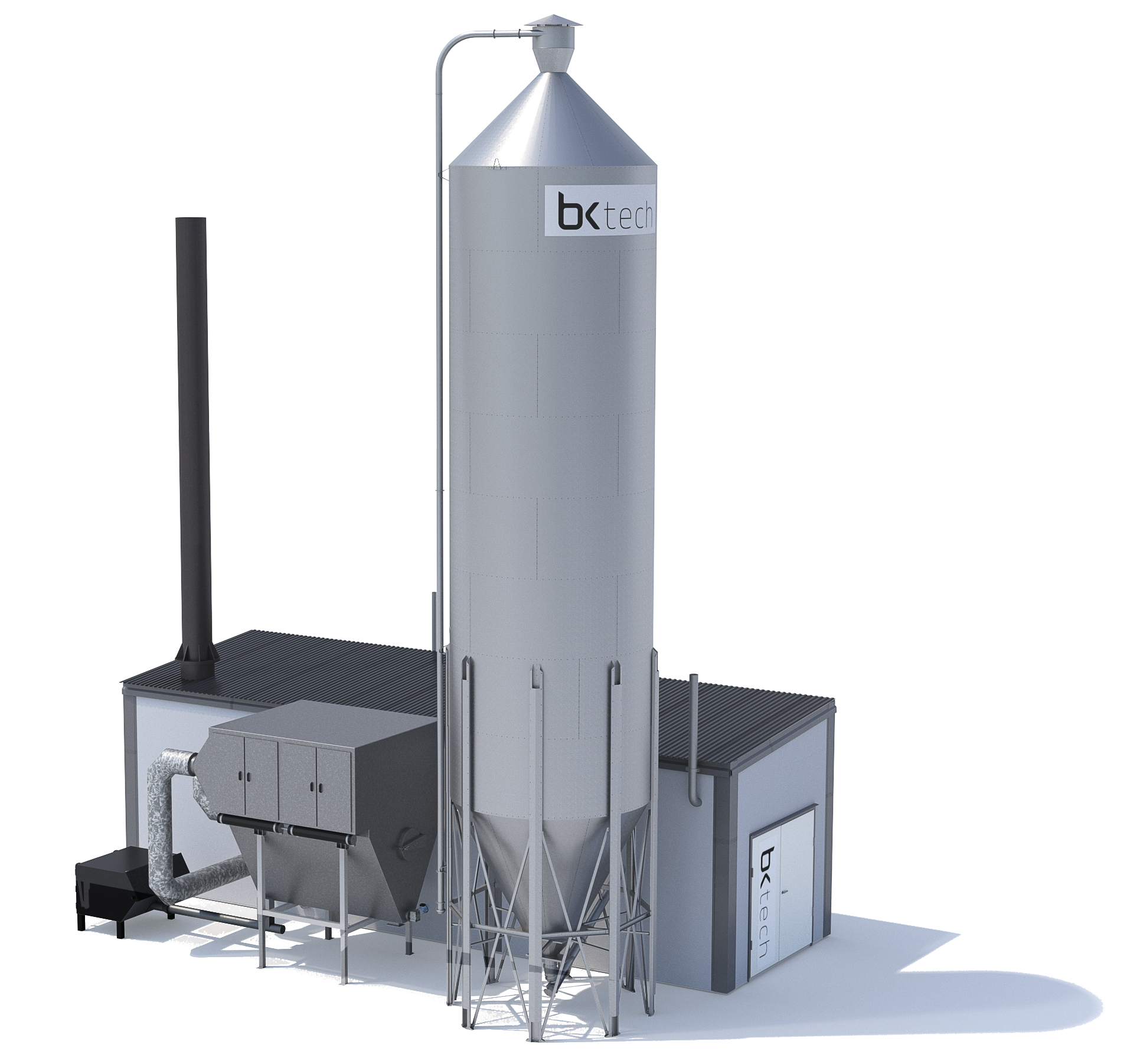

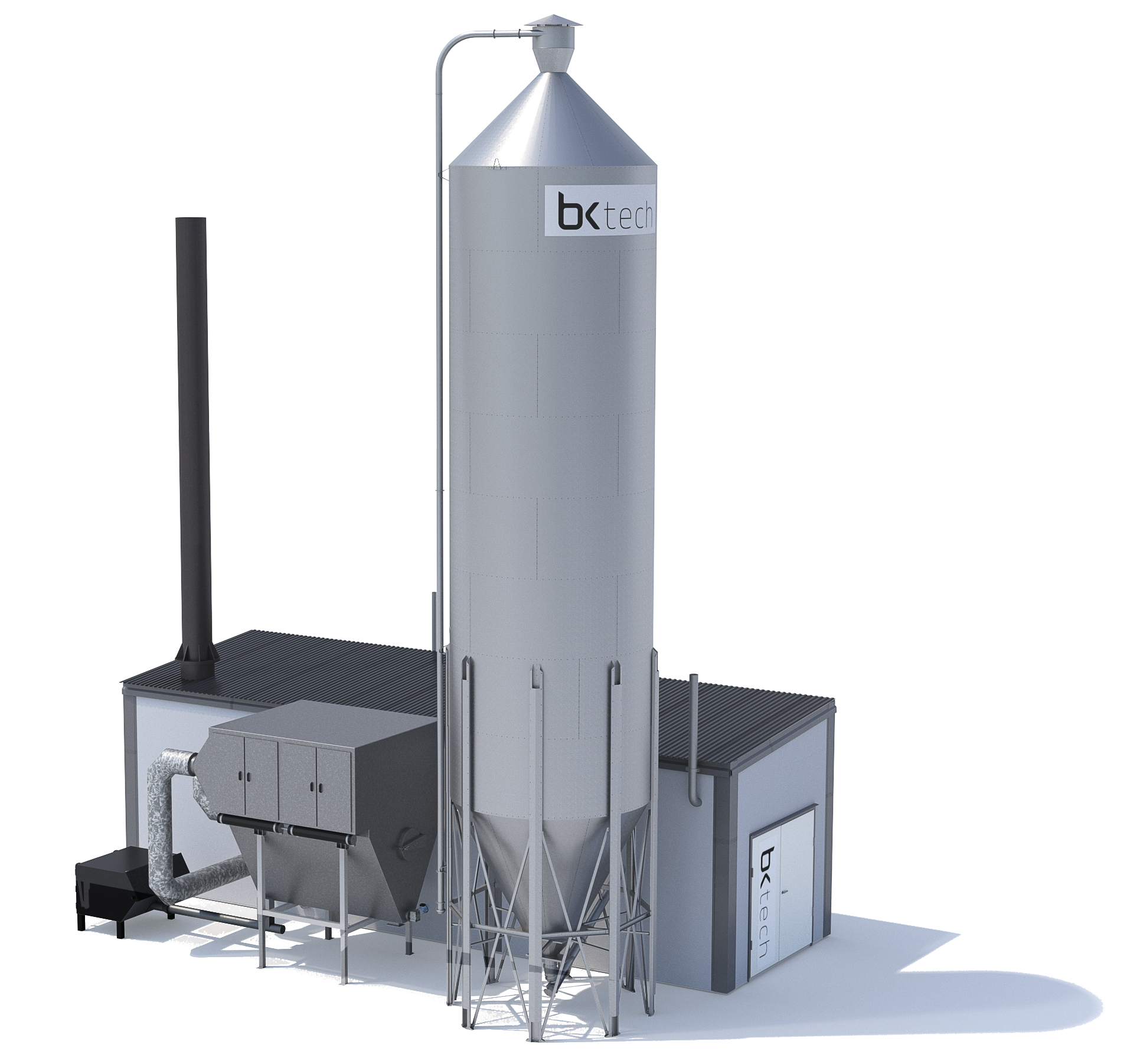

BKtech BioOne HW 500 kW for the production of hot water

Interesting facts:

In addition to going fossil-free and cutting energy costs, production capacity has also increased.

The process

BKtech delivered a bioenergy plant that produces bioenergy in the form of hot water. What is of special interest is that the plant runs on waste from ESS-ENN Timber’s own production: During manufacturing, some residual products and unusable wooden parts fall out. Wood chips are therefore derived from these residues and used as biofuel in the plant. Biofuel does not get much more locally produced than this!

The result

Thanks to the new plant with a pressure of a whopping 6 bar, ESS-ENN Timber has been able to increase the temperature of its glue jointing machines and thus increase its production capacity. The fact that they have become completely fossil-free at the same time has also resulted in significant energy cost savings. This is what we call a win-win situation for both the climate and the wallet.

-93%

-65%

Generic fuel savings, not related to a specific reference case.

Any questions about the project?

Get in touch with:

Andreas Åström

Project Coordinator

More cases

”Lulles” – Ludvig Sörensen

Abetong

Atria Borås

Crispo Paper AB

CWS Sweden AB

ESS-ENN Timber AB

Falköpings Mejeri

Gudruns kött & charkuterier

Guldfågeln AB

Henkel Sweden Operation AB

High Coast Distillery

IWB Bahnhof

Krönleins Bryggeri AB

Luleå Energi

Nya Lantfågel på Österlen

Skövde Slakteri

Stranda Kyckling AB

Svenska Lantchips AB

Tevsjö Destilleri

TopCell AB

Välinge Innovation Sweden AB

Vätternpotatis

VPK Packaging AB through VPK Group, Bäckefors Sweden

Wermlands Mejeri

Further companies that use our solutions