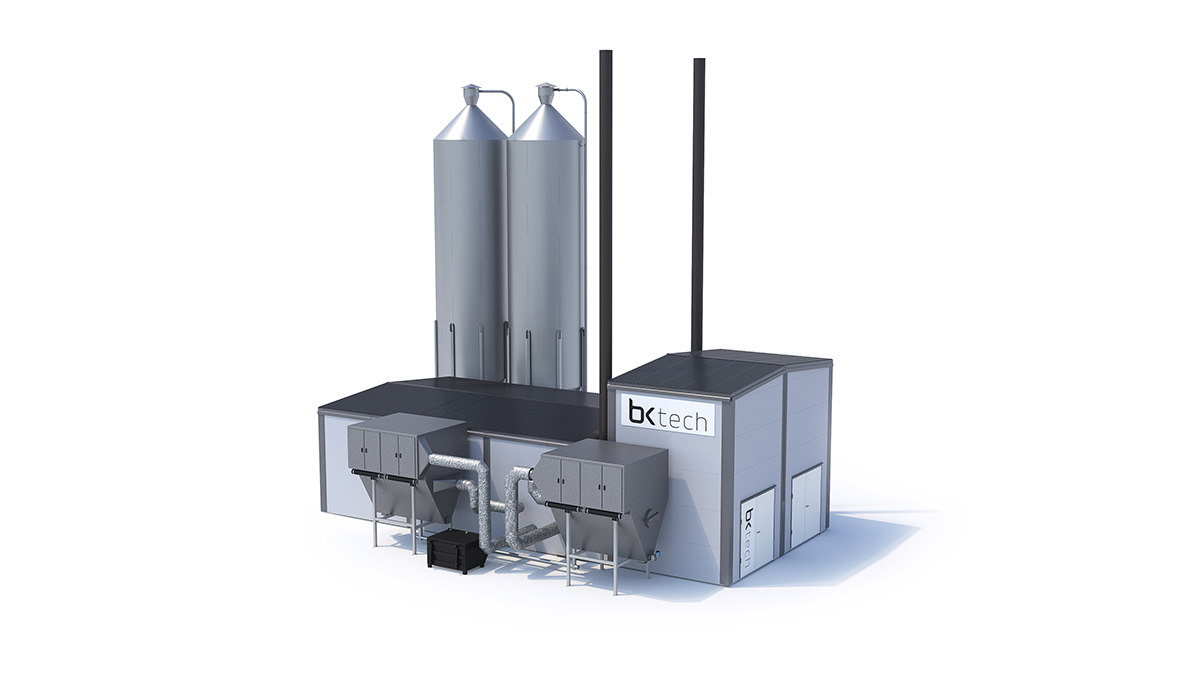

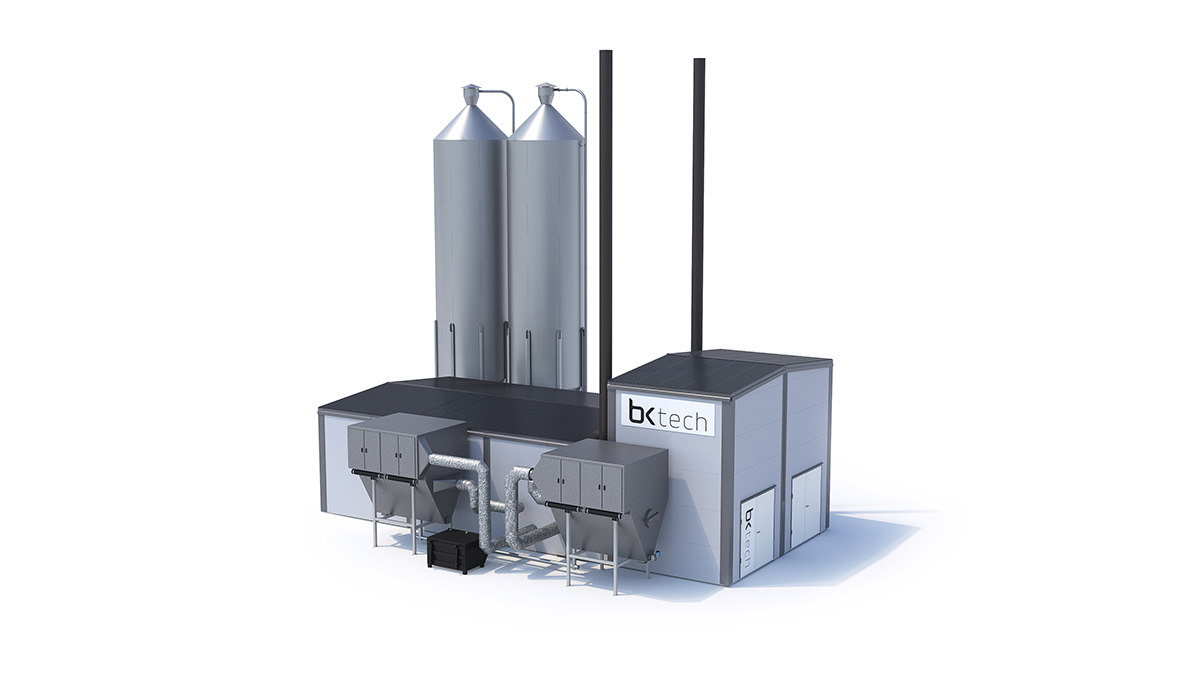

BioTwin

BioTwin relies on the very same technical foundations as BioOne, but it comes equipped with double bio-boilers for wood pellets – hence the name. BioTwin is available in 3 or 4 MW models and it is up to you to determine the type of production: steam, warm water, hot water or hot oil.

Climate-friendly bioenergy

BKtech’s BioTwin is a modular bioenergy plant for efficient, reliable and climate-friendly energy production. As we manufacture and optimise our plants at our own state-of-the-art factory in Blomstermåla, we are able to make quick deliveries and installations throughout Sweden and beyond. All components in our plants are manufactured in the Nordic countries, and Siemens supplies our PLC systems for control and monitoring. A high-performance system combined with intelligent control allows the plant to handle rapid load variations in a very flexible and stable way. Automated processes and minimal maintenance requirements contribute to excellent availability, high thermal efficiency and secure energy supply.

Two modules

BKtech’s BioTwin is generally supplied with an 85 m3 wood pellet silo, which equates to 540 MWh of energy. This bioenergy plant consists of two modules that are manufactured and assembled in our production facility in Småland, Sweden. BioTwin features high-quality components, 2 burners from well-known Ariterm, PLC systems from Siemens and bio-boilers from Swedish supplier VEÅ.

Little preparatory work required

This plant is generally delivered by truck according to European standards. BKtech has established a number of partnerships with both carriers and contractors to help with transportation. In addition, BKtech’s BioTwin is easy to install. It takes little preparation, most often just a cast slab on which we place the bioenergy plant, and BioTwin is equipped with connectors and flanges to be linked to the end client’s own system.

Small footprint

We at BKtech have developed BioTwin with the aim of achieving as small a footprint as possible. BioOne measures 7.5m in width, 12m in length and has a height of 4.1m, chimney and silo excluded. BioTwin can also be disassembled and relocated, allowing the bioenergy plant to be sold on, should such a need arise. Modular bioenergy plants lead to lower project costs for the end client thanks to very few preparatory steps, fast deliveries and effective integration with the client’s own systems.

Technical advantages

Financial advantages

Environmental advantages

Case

”Lulles” – Ludvig Sörensen

Abetong

Atria Borås

Crispo Paper AB

CWS Sweden AB

ESS-ENN Timber AB

Falköpings Mejeri

Gudruns kött & charkuterier

Guldfågeln AB

Henkel Sweden Operation AB

High Coast Distillery

IWB Bahnhof

Krönleins Bryggeri AB

Luleå Energi

Nya Lantfågel på Österlen

Skövde Slakteri

Stranda Kyckling AB

Svenska Lantchips AB

Tevsjö Destilleri

TopCell AB

Välinge Innovation Sweden AB

Vätternpotatis

VPK Packaging AB through VPK Group, Bäckefors Sweden

Wermlands Mejeri